Transom, Flanges, Floors and Girder

There was some contemplating on where to attach the transom. On the deck or the hull. It was decided that it would be best to attach it to the deck. This however meant that the 15th frame needed to be moved forward by the thickness of the transom, glass and resin. This wasn’t a major issue. We also had to figure out the shape of the transom. Chris showed us a few simple methods by using a flat piece of wood or board and a scribing tool to make point on it and transferring the point and connecting them with a batten. We used the same method for the collision bulkhead. After we got the exact shape of the transom we cut it out of foam and glued it to the deck.

The flanges we made ran along the deckline from the bulkhead aft down from the topside 15mm which is the thickness of the deck and down where the transom gets attached to the flange. There is another flange running on top of the girder to which the cockpit sole will be attaching to. I made blocks which I screwed on the frames which was hanging over the topsides at the correct angle of the deck camber, which I got using my sliding bevel and bevel board, to which a long piece of MDF runs along the deck line 16mm down from the topside. The MDF was scribed and cut out to the shape of the deck and cut 50mm wide. The flange is EDB 100mm glass tape. This meant that 50mm of the tape will be on the topside and 50mm on the underside of the MDF which is set on the angle of the deck camber. Before the flange was made a piece of double sided tape was stuck to the underside of the MDF and the peel-ply was stuck to it. Then we made a cove on the inside to glass over it and peelply. Once done the resin cured the peel-ply and blocks were removed and the flanges were sanded smooth.

The Girder where made out of foam and was glassed both sides with the vacuum. The girder runs down the centre of the boat from the transom to the centrecase and it’s glued in and coved with rubberized-epoxy. It also keeps the cockpit-sole up in place and also gives the boat and cockpit more stiffness. There is a flange on the top of the girder which the cockpit sole will be glued to once the deck is fitted to the hull.

The floors are strips of foam which is hot-glued to the hull to keep the shape of it and the edges are rounded out and coved for glassing. There is a strip of carbonfibre uni as wide as the foam running on top of the foam and the fiberglass is glassed over the carbonfibre and the foam. The strips of foam runs athwart ship (across the beam) of the boat. The floors holds the shape and stiffens up any flexibility the boat might encounter in the water when hitting the waves. There is also a stack on the floors because it is vacuumed on the hull

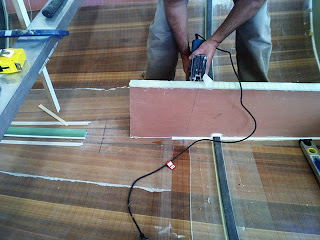

very good description . It would have been your best blog yet if you would have described each photo. These photos show in detail the build process.

ReplyDelete